Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

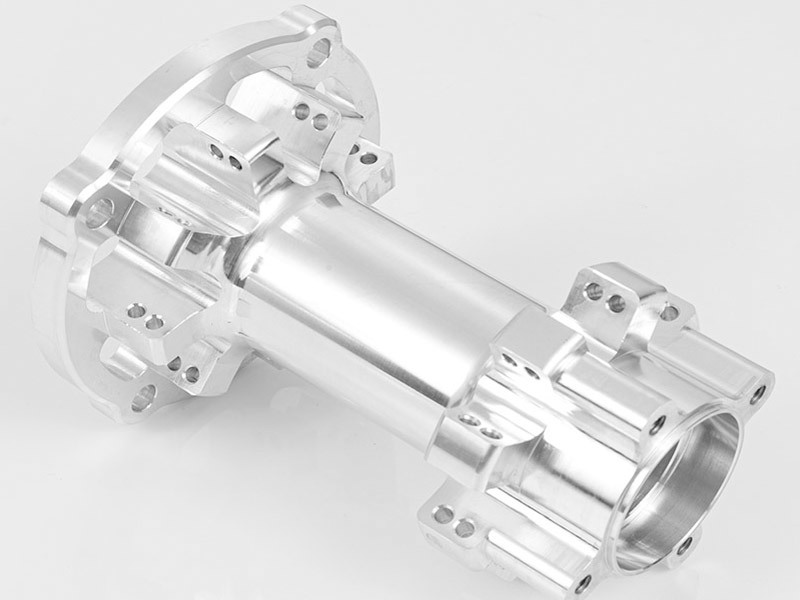

High Volume CNC Machining Services

What is CNC 5Axis?

CNC 5Axis machining is a type of computer numerical control (CNC) machining that involves the use of a 5-axis machine to create complex parts and shapes from a variety of materials. The 5-axis machine is capable of rotating on five different axes, allowing it to cut and shape materials from various angles and directions.

One of the key advantages of CNC 5Axis machining is its ability to create complex geometries with a high degree of accuracy and precision. This makes it an ideal choice for the production of high-quality parts for a variety of industries, including aerospace, automotive, and medical.

In addition to its precision and accuracy, CNC 5Axis machining is also highly efficient and cost-effective. With its ability to complete multiple operations in a single setup, 5Axis machining can help reduce production times and costs while improving overall quality and consistency.

At our CNC machine shop, we offer high-quality 5Axis machining services that are tailored to meet the unique needs of our clients. With our state-of-the-art equipment and experienced machinists, we are able to deliver superior results that meet the highest standards of quality and precision.

5-axis CNC milling

5-axis CNC milling centers can produce parts with complex geometries and increase productivity by minimizing the number of machine setups.

Maximum part size for 5-axis CNC milling

|

Size |

Metric units |

Imperial units |

|

Max. part size for all materials |

500*450*400 |

25.5 x 25.5 x 11.8 in |

|

Min. feature size |

Ø 0.50 mm |

Ø 0.005 mm |

High Quality 5Axis CNC Machining Service

When it comes to producing high-quality parts and components, CNC 5Axis machining is the way to go. With its ability to create complex geometries with a high degree of accuracy and precision, 5Axis machining is ideal for the production of parts for a variety of industries.

At our CNC machine shop, we specialize in providing high-quality 5Axis machining services that are tailored to meet the unique needs of our clients. Whether you need custom parts for aerospace, automotive, or medical applications, we have the expertise and equipment to deliver superior results.

Our team of experienced machinists and engineers work closely with our clients to understand their specific needs and requirements. From the initial design phase to the final product, we are committed to providing exceptional service and quality.

In addition to our 5Axis machining capabilities, we also offer a range of other machining services, including prototyping, rapid prototyping, and EDM machining. With our state-of-the-art equipment and advanced technology, we are able to deliver efficient, cost-effective solutions that meet the highest standards of quality and precision.

How 5Axis CNC Milling Works

5Axis CNC milling is a type of computer numerical control (CNC) machining that involves the use of a 5-axis machine to create complex parts and shapes from a variety of materials. The 5-axis machine is capable of rotating on five different axes, allowing it to cut and shape materials from various angles and directions.

The process of 5Axis CNC milling begins with the creation of a digital model of the part or component that is to be produced. This model is then loaded into the 5-axis machine, which uses advanced software to generate a toolpath for the milling process.

Once the toolpath is generated, the machine begins the milling process, using its five axes to rotate and move the cutting tool in multiple directions and angles. This allows the machine to create complex shapes and geometries with a high degree of accuracy and precision.

Throughout the milling process, the machine constantly monitors and adjusts its movements to ensure that the part is being produced to the exact specifications of the digital model. This ensures that the final product meets the highest standards of quality and precision.

At our CNC machine shop, we have the expertise and equipment to deliver superior 5Axis CNC milling services that meet the unique needs of our clients. From aerospace and automotive to medical and other industries, we are committed to providing efficient, cost-effective solutions that meet the highest standards of quality and precision.

Our 5-axis CNC milling service capabilities are state-of-the-art and designed to meet the needs of even the most demanding projects. We use the latest 5-axis CNC milling technology to provide our customers with precision parts that meet their exact specifications. Our team of skilled machinists and engineers work with our clients to develop custom solutions that are tailored to their unique requirements.

Our 5-axis CNC milling machines are equipped with high-quality tooling and advanced software that allows us to produce complex geometries with tight tolerances. We specialize in the machining of aluminum, anodized aluminum, and other high-performance materials.

Our rapid prototyping capabilities allow us to produce prototypes quickly and efficiently, so our clients can test and refine their designs before moving into production. We can also produce small and large production runs with fast turnaround times, thanks to our streamlined production processes.

Our commitment to quality is reflected in every part we produce. We use the latest inspection equipment to ensure that each part meets our strict quality standards before it leaves our facility. Our CNC machining services are ISO certified, ensuring that our processes and procedures meet the highest industry standards.

Whether you need a single prototype or a large production run, our 5-axis CNC milling service capabilities can meet your needs. Contact us today to discuss your project and learn how we can help you achieve your manufacturing goals.

What’s the 5Axis advantages?

5-axis machining refers to the use of a computer numerical control (CNC) machine tool that can move a part or cutting tool along five different axes at once, allowing for greater precision and flexibility in manufacturing processes. Some advantages of 5-axis machining include:

1. Greater accuracy: 5-axis machines can produce highly accurate parts with tight tolerances, as the tool can move in multiple directions simultaneously, allowing for more efficient and precise cutting.

2. Increased productivity: With the ability to perform multiple operations in one setup, 5-axis machines can reduce cycle times and increase overall production throughput.

3. Improved surface finish: The ability to tilt and rotate the cutting tool allows for better access to difficult-to-reach areas, resulting in a smoother and more consistent surface finish.

4. Reduced setup time: 5-axis machines can perform complex machining operations in a single setup, reducing the need for multiple setups and tool changes.

5. More design flexibility: 5-axis machines can produce complex parts with intricate shapes and contours that would be difficult or impossible to achieve with traditional machining methods.

Overall, 5-axis machining offers numerous advantages that can help manufacturers improve efficiency, quality, and profitability.